Introduction

The design of tunnelling rounds is both difficult to optimise and time consuming.

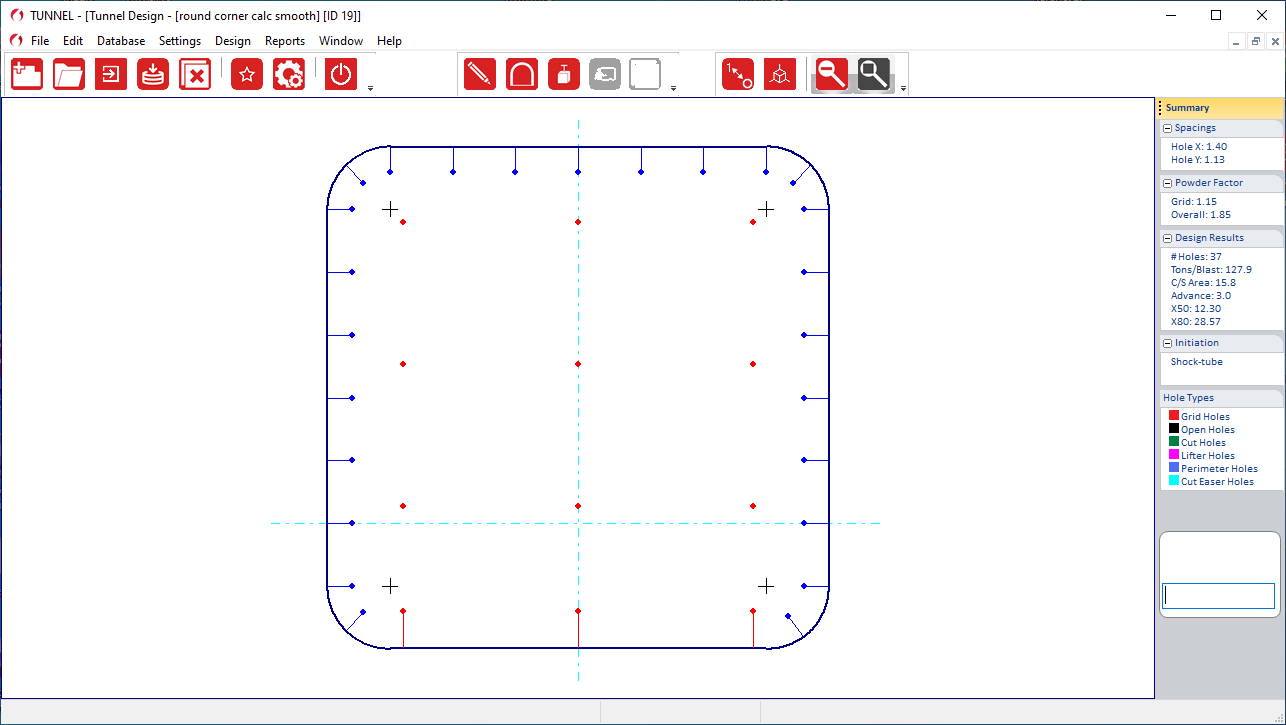

AECI Mining Explosives developed the TUNNEL software to assist its blasting engineers with the design and optimisation of tunnel blast layouts in mining and civil applications.

It is assumed that the user is proficient in this topic and will apply their engineering judgement to the suitability of the design.

Guidelines for tunnel design are provided in the AECI Mining Explosives Tunnelling Handbook.

The package, which grew through years of experience and learning, contains unique design features.

Using this software the blasting engineer can rapidly

- Develop an appreciation for the finer points of design

- Define the perimeter of the tunnel to be blasted

- Optimise the number and position of the blast holes

- Address the charging of the blast holes

- Obtain the efficiencies and cost of the design

- Estimate fragmentation

The outputs include

- Scaled printout diagrams of the layout of the blast holes

- Tabular printouts of hole design parameters

- Analysis of blasting efficiencies include:

- Powder factors

- Volume and tonnages blasted

- Explosive consumption

- Drilling requirements

- Initiating system requirements

- Mean fragmentation estimates

Direct Data Import

This tool allow the user to import the co-ordinates of the desired profile /outline directly from an external source such as a CAD or Mine plan software suite,

the requirement of the point co-ordinates are that they are comma separated and contain three values for the X,Y & Z values.

What is TUNNEL Blast Design Software

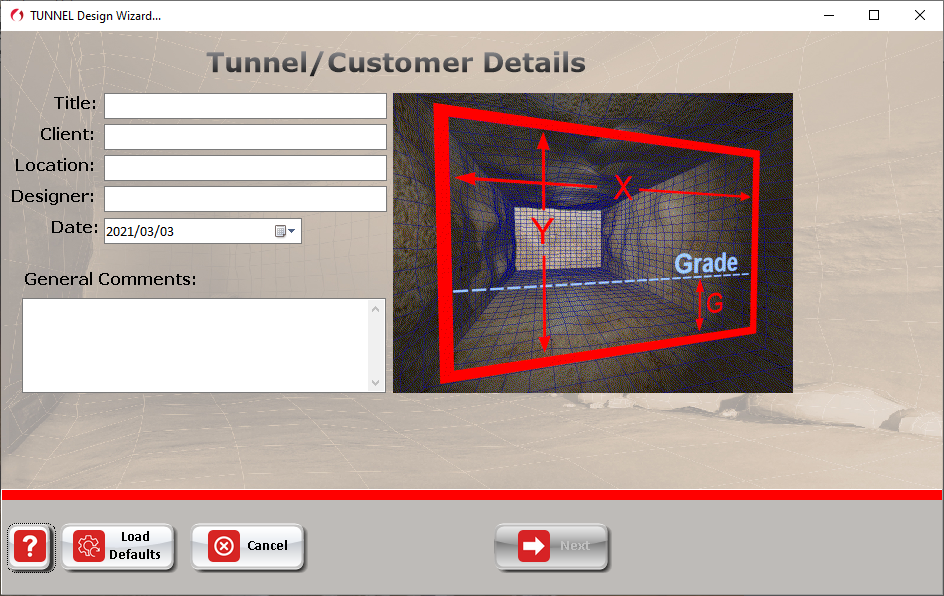

The TUNNEL software follows a logical sequence when designing a tunnel. The process steps for most designs will be as follows:

- Database: Material and product that will be used in the design.

- General Information: All the relevant information that will be required to identify a blast

- Wizard: Tool used to guide the user through a design.

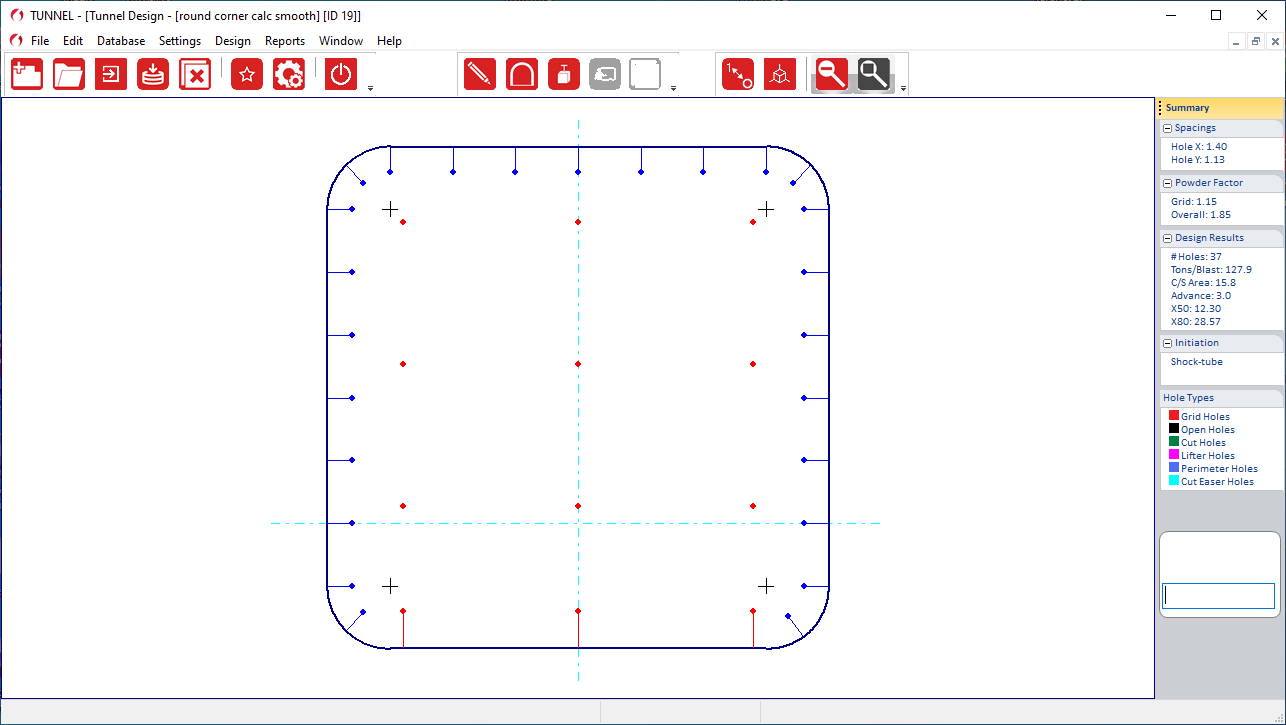

- Create Design Layout: On completion of the Wizard, check the design presented by AEL Tunnel and make any necessary changes to the basic layout. These changes include moving/adding/deleting holes and changing hole types.

- Insert Cut: Users can choose from pre-defined cuts or design and insert a cut of their own choice.

- Design Check: Check the design and ensure if it is correct by applying engineering judgement. Remember AEL Tunnel is a Computer Assisted Design system and not a substitute for an experienced blasting engineer.

- Timing: Assign timing delays to design or export the holes to AEL Tie-Up for timing evaluation.

- Report: Print the final design and reports.

The Design Wizard guides you through all the steps in order to complete the design and simplify the complete design process.

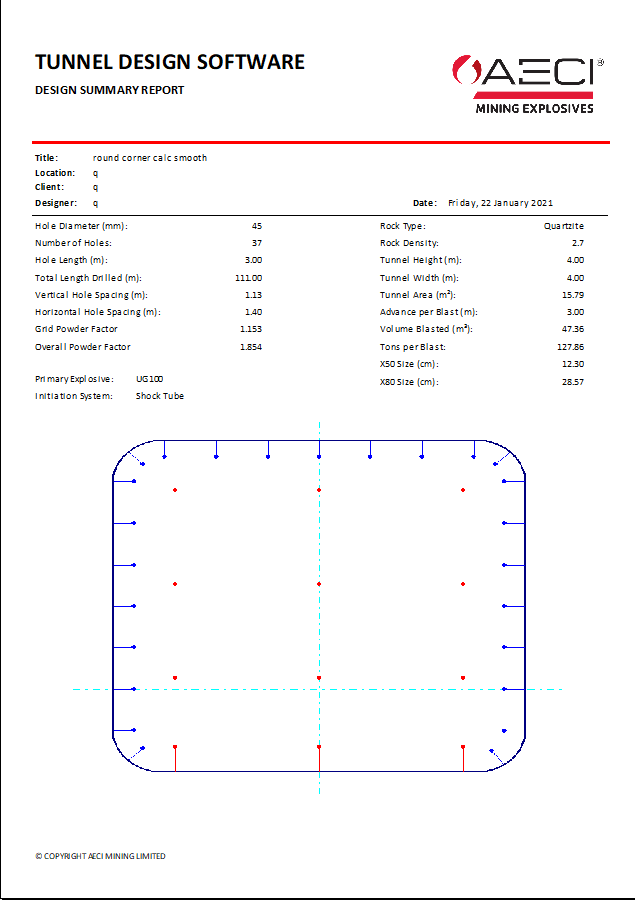

Reporting

The User can run numerous reports in order to confirm or determine whether the design is at its most optimum.

One can even compare different designs to each other to enable more informed decisions

- Design summary report

- Hole Parameters Report

- Drilling Summary Report

- Explosives Consumption Report

- Initiation and Extras Summary Report

- Full Report

- Design Comparison Report

Key features

- Simplified design process

- Distinction of hole types

- Reporting

- Costing Functions

- Immediate graphical view of design

- Timing feature

System requirements:

Minimum system requirements

- Windows 7 32bit Operating system

- Pentium processor

- 2GB RAM

- VGA 1024x768

- 200MB free space on hard disk

Recommended system requirements

- Windows 10 64bit Operating system

- Quad Core processor

- 4GB RAM

- HDMI 1920x1080

- 250MB free space on solid state drive