Introduction

Designer is a software tool available to all AECI Mining Explosives Representatives to be able to produce consistent and

relevant blast designs based on sound engineering principals.

The design of surface blasting is both difficult to optimise and time consuming.

We developed Designer software to assist our blasting engineers with the tools for optimisation of designs in surface mining applications.

The package, which grew through years of experience and learning, contains unique design features.

A powerful feature of the software is the ability to examine what-if situations by easily changing blasting parameters such as hole size,

explosive type and initiating system type to visualise the effects on the expected outcome.

This is an extremely powerful and useful tool to evaluate ways to improve specific areas of the blast results.

Using this software the blasting engineer can rapidly:

- Develop an appreciation for the finer points of design

- Define the permutations of the in-situ rock to be blasted

- Optimise the number and relationship of the blast holes

- Address the charging of the blast holes

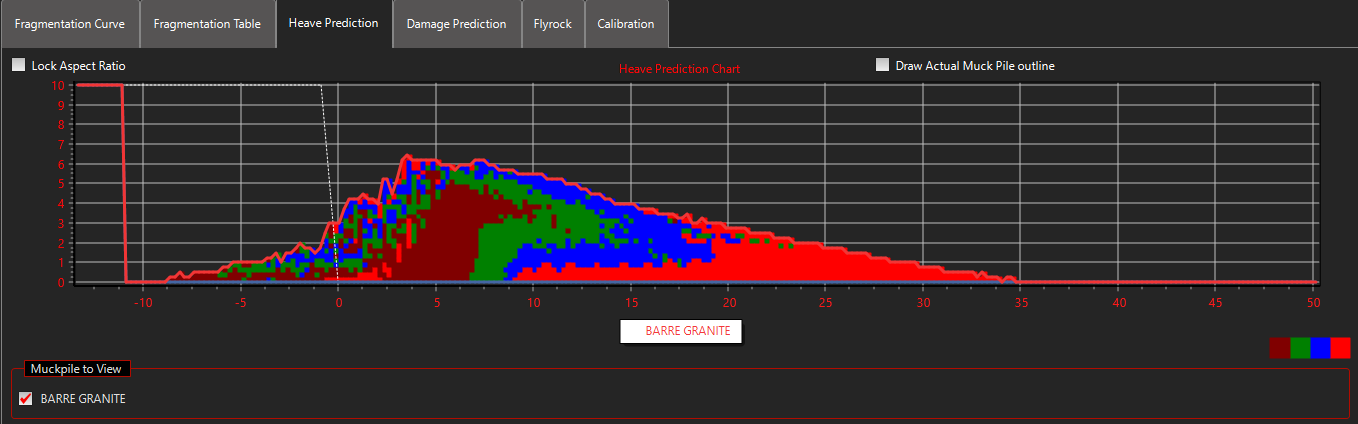

- Compare the predicted heave profile against the actual achieved results

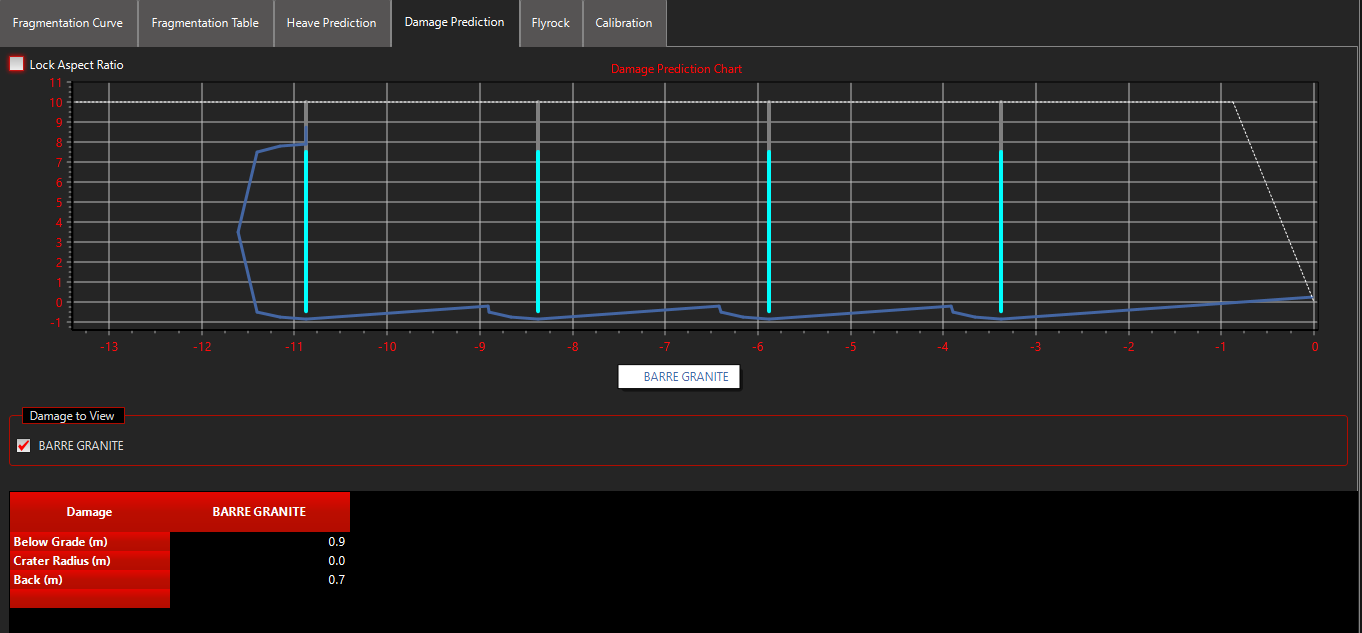

- Understand damage extents

- Cater for multiple rock types in a single blast

- Allow for deck loading

The outputs include:

Colaborate with colleagues by sharing files

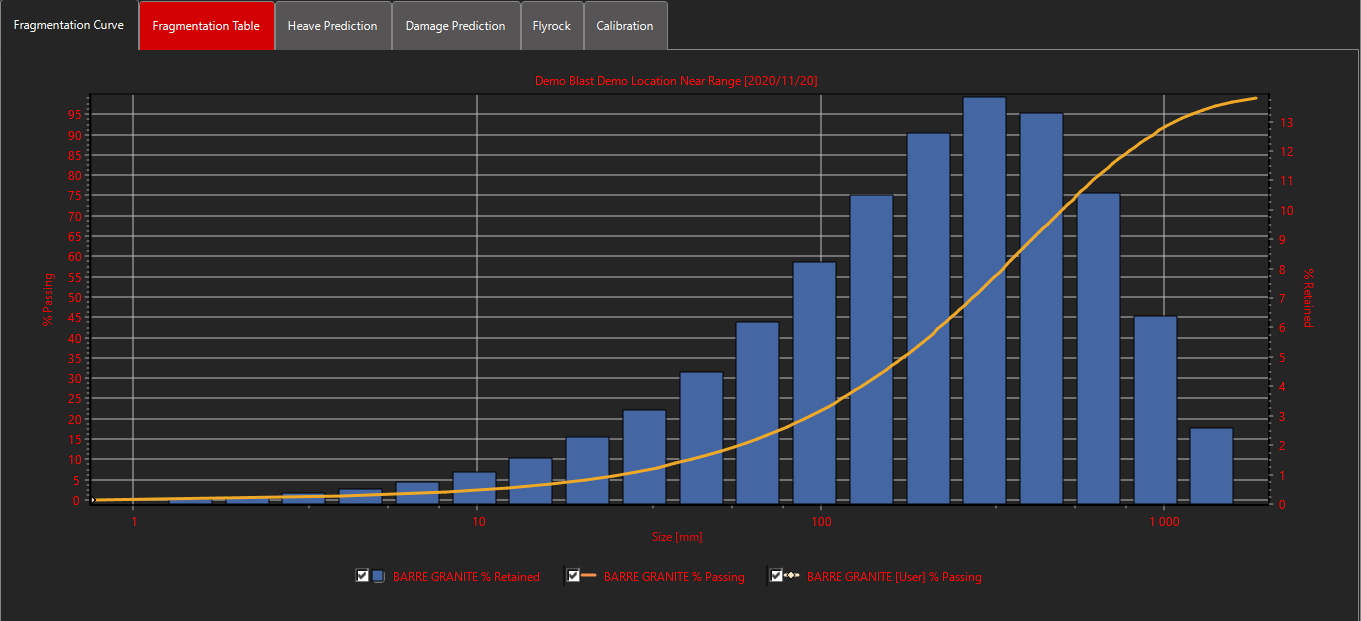

Customisable sieve sizes for the fragmentation analysis to suit your specific needs

Generate reports per blast, per mine or per customer

- Digital reports of the blast design parameters

- Analysis of blasting efficiencies including:

- Powder factors

- Mean fragmentation estimates

- Percentage cast

- Muckpile movement

Comparitive reports to view the effects of changes to the designs in a tabular format.

Benefits:

- Online updating to the latest release of the software

- Database of designs for easy retrieval of previous designs

- Spreadsheet reporting for use in recommendations

- Consistent application of blast design principles

What is Designer Software

The Designer software follows a logical sequence when designing a blast layout. The process steps for most designs will be as follows:

- Database: Material and product that will be used in the design

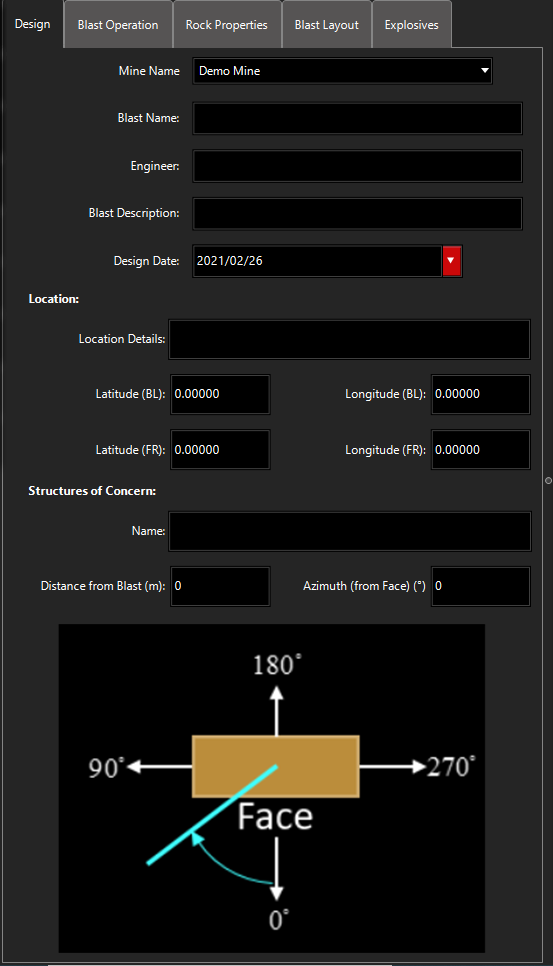

- General Information: All the relevant information that will be required to identify a blast

- The details necessary to define the blast including the height, width, hole length, hole diameter, rock type(s), face angle, etc.

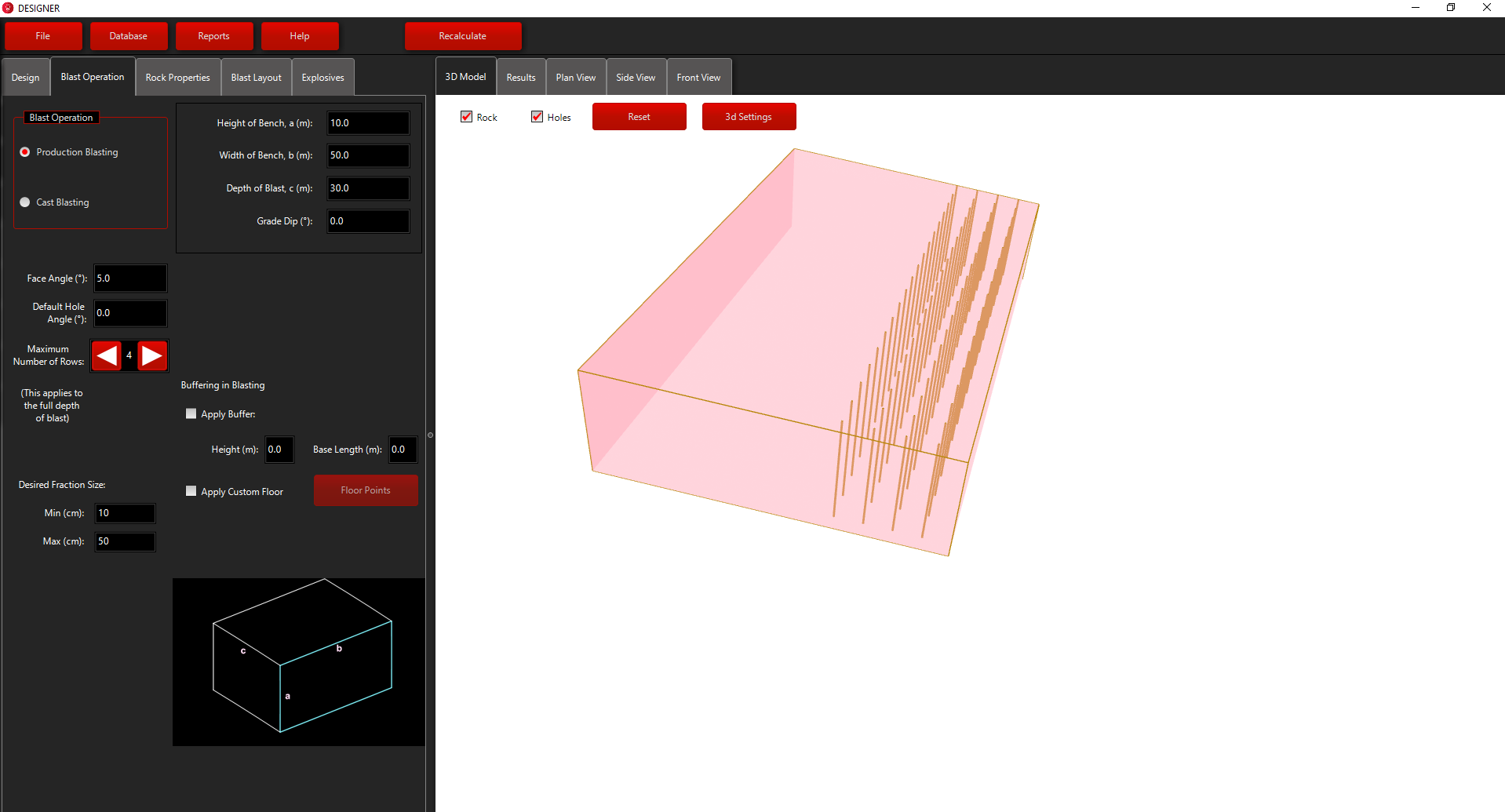

- Create Design Layout: Immediate graphical representation tools to visualise a 3 Dimensional view of the blast area

- Design Check: Check the design and ensure if it is correct by applying engineering judgement.

- Report: Print the final design and reports

Key Features

All designs are specific to a customer and mine name.

- Database

- Simplified design process

- Reporting

- Cast blast timing optimisation

Different blasting conditions can be selected for the specific design including:

- Type of blast

- Size of blast

- Different rock types within the blast site

- Individual properties for the different rock types

- Suggested rule of thumb guidelines based on:

- Minimum and maximum rule of thumb guidelines

- Explosive properties as evaluated and approved by AECI Research and Development

- Allowance for deck loading

- 3 Dimensional representation of the blast area as defined

- Predictive fragmentation curves and tables to a customisable sieve size

- Plan-, side- and front view of hole layout in the given blast volume

- Graphical represention of predicted fly-rock risk zones

- Cast blast timing optimisation

- 3 Dimensional representation of the muckpile profile

- Suggested burden timing for optimal fragmentation

- Scatter of pyrotechnic initiation systems included in the fragmentation predictions

System requirements:

Minimum system requirements

- Windows 7 32bit Operating system

- Pentium processor

- 2GB RAM

- VGA 1024x768

- 200MB free space on hard disk

Recommended system requirements

- Windows 10 64bit Operating system

- Quad Core processor

- 4GB RAM

- HDMI 1920x1080

- 250MB free space on a solid state drive